IUXTA IMPLANTS

subperiosteal implants

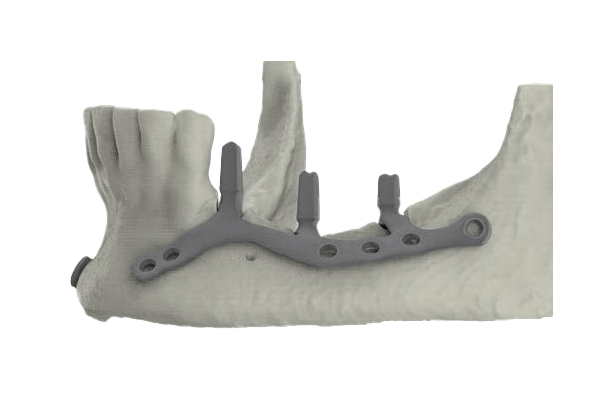

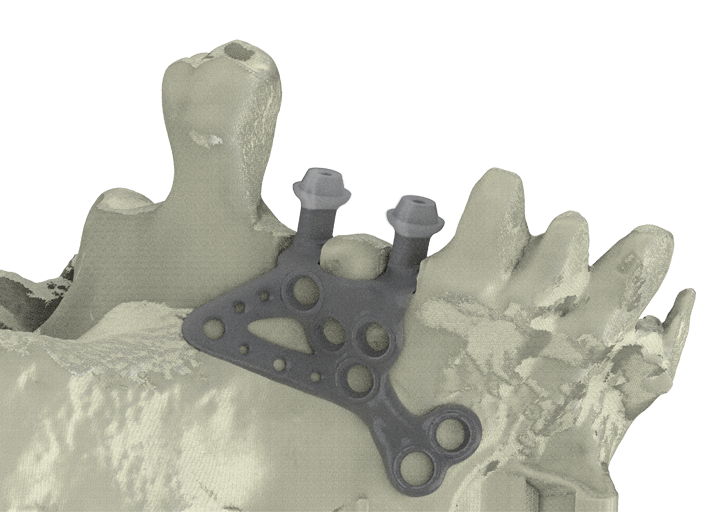

Unlike classical and more well-known endosseous implants, the Iuxta implants are positioned subperiosteally, they are placed by taking advantage of the morphology of the bone structure and subsequently fixed to the bone with the use of osteosynthesis screws.

subperiosteal implants

Another possibility of implant

This siitable solution is considered by the clinician in order to resolve rehabilitation cases in patients who suffer from severe bone atrophy and who consequently cannot be treated with classical implant surgery. Moreover, these patients can rarely undergo such extensive and complex regenerative procedures: these operations entail very long recovery times and they do not have acceptable guarantees of success.

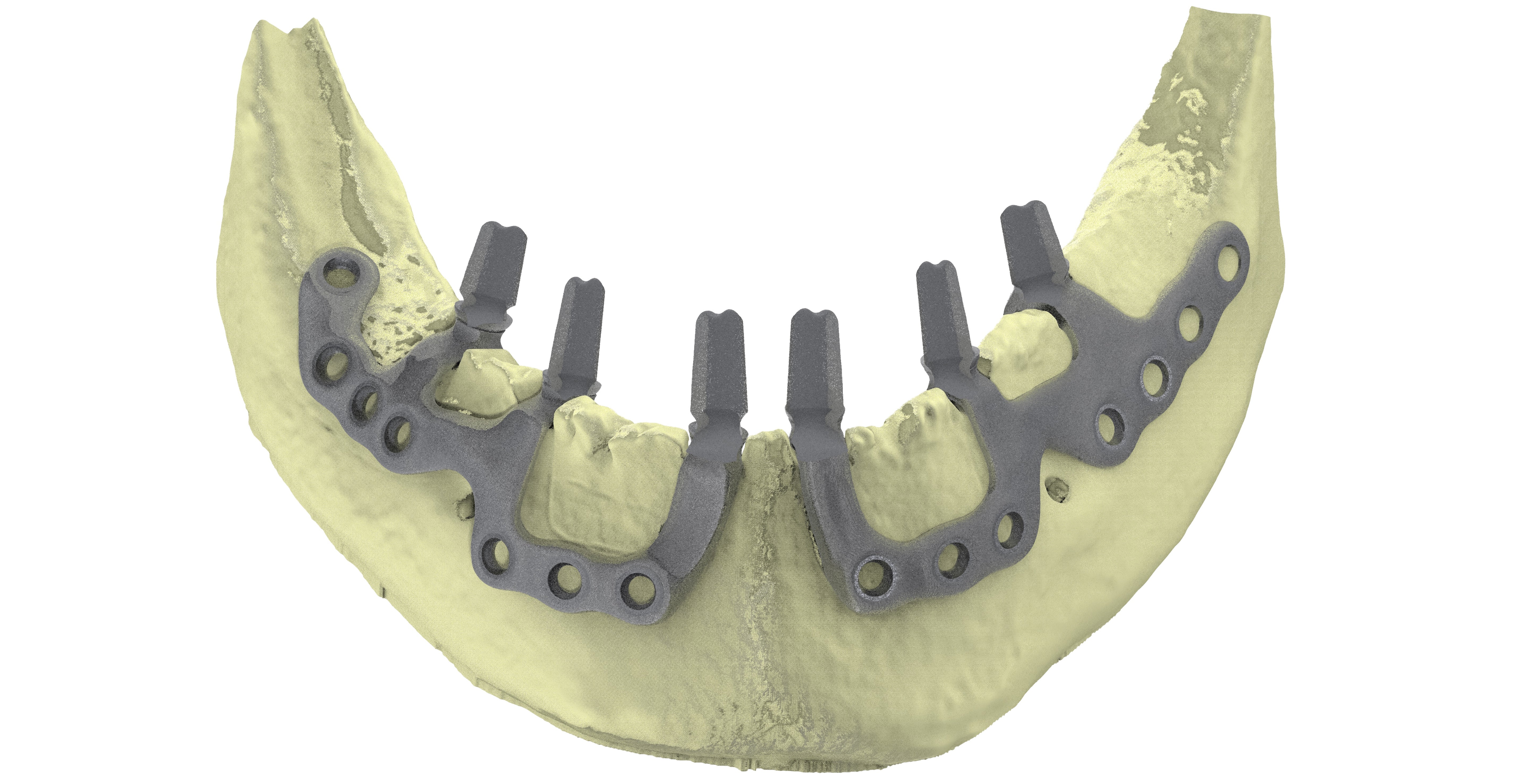

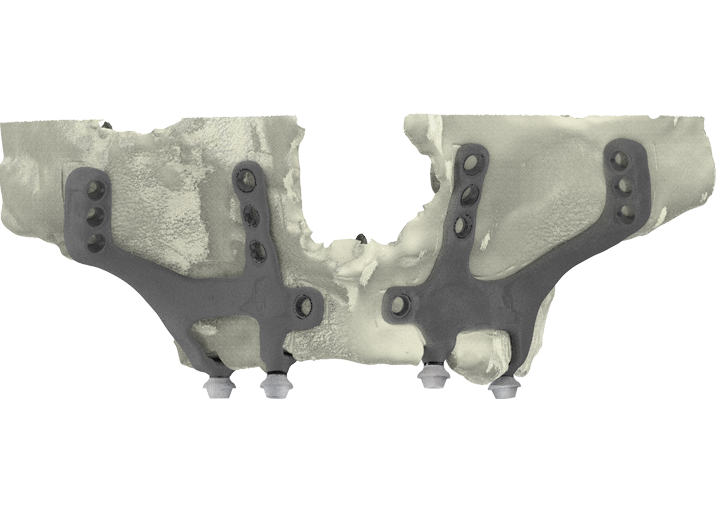

IUXTA IMPLANT

TYPES OF GRIDS

During the creation of the project it is important to decide the type and dimension of the Iuxta implant, based on the 3D radiographic images and on the agreed prosthesis rehabilitation of the patient by the clinician.

Total rehabilitation

Hemiarch

2-Element rehabilitation

Single-element

IUXTA IMPLANT

TYPES OF ABUTMENTS

SINGLE-STAGE ABUTMENTS FOR CEMENTATION

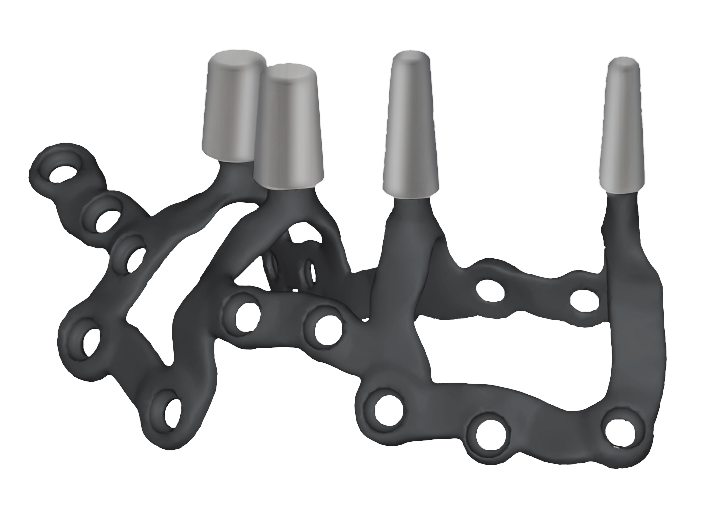

All abutments used on Iuxta implants are rectified by a 5-axis bur, guaranteeing reproducible geometries and mathematics, thus avoiding potential errors that could occur during the manual processing phase.

TWO-STAGE ABUTMENTS FOR SCREW-RETAINED PROSTHESES (MUA)

As per the single-stage abutments for cementation, these abutments for the screw-retained prosthesis are checked by a 5-axis bur. These abutments precisely reproduce the shape of classic abutments for screw-retained prostheses, that is, MUA. The locking screw on the abutments is bigger compared to classical ones by 1.4 times.

CYLINDRICAL ABUTMENTS WITH CONICAL COUPLING MORSE TAPER

The cylindrical abutment with conical coupling morse taper favours healing of soft tissue and allows for the use of all rotational abutments that permit a screw-retained, cemented and conometric prosthesis to be created.

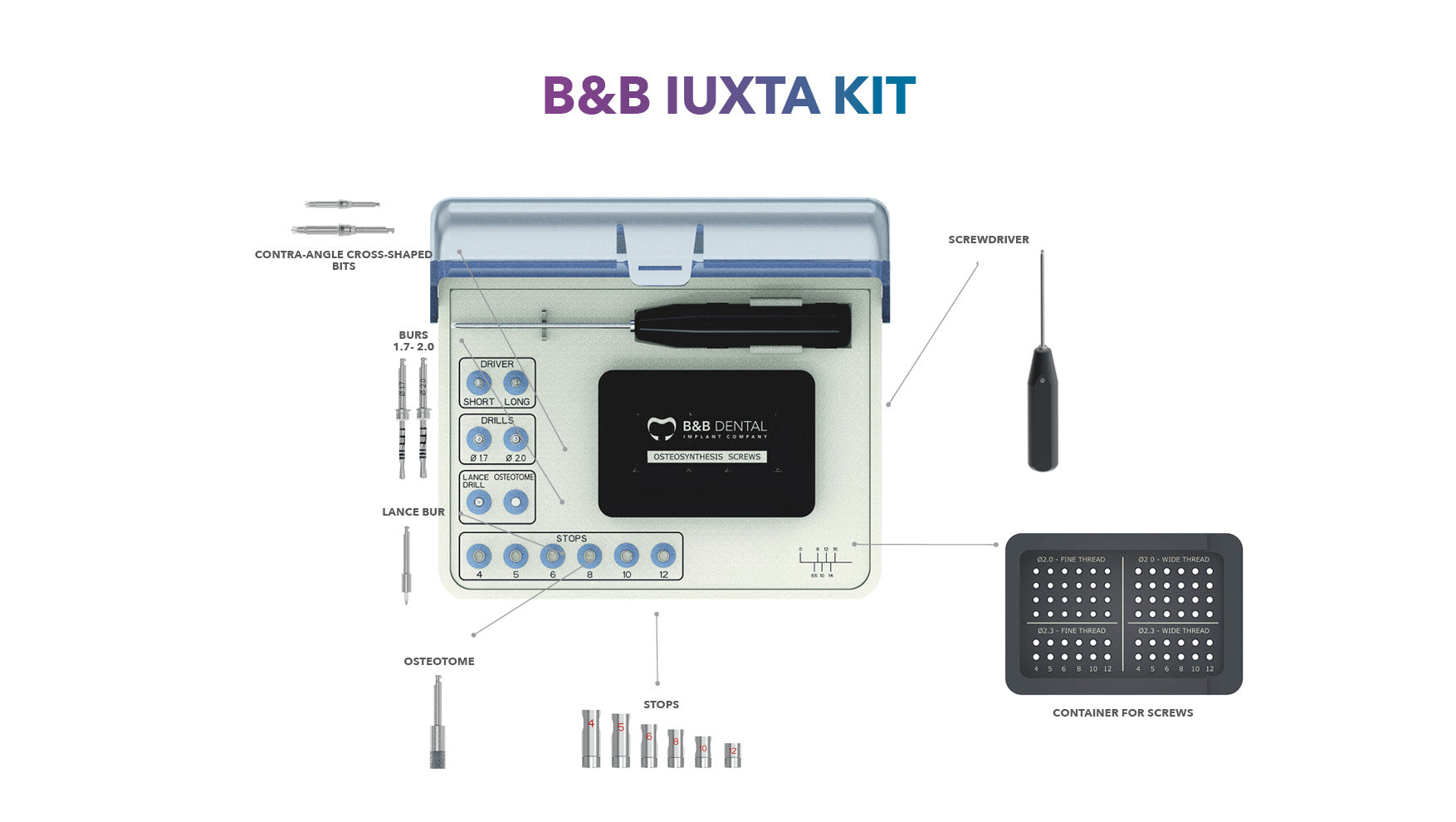

IUXTA IMPLANT

WORKFLOW

1. DATA COLLECTION

The tomographic imaging of the patient is essential for creating the Iuxta implants. During the examination, the patient wears a dedicated radiological guide that allows for matching during the design phase of the implant that is prosthetically guided. The acquired DICOM files are sent to us to check the feasibility of the project.

2. DIGITAL DESIGN

The grids are designed with the help of dedicated software in accordance with the patient’s anatomy by studying prosthesis loads. The project is shared with the dentist, who can make necessary changes before production takes place.

3. SLM PRINTING

The Iuxta grids are produced in titanium via laser melting to guarantee high purity, microstructural homogeneity, and mechanical strength. Each grid is laser-printed with an alphanumeric code that uniquely matches it to the patient it is designated for.

4. PROCESSING AND SHIPPING

Iuxta grids are cleaned and decontaminated by automatic ultrasound machines in a controlled atmosphere in clean rooms. All production cycles are monitored and registered to ensure product traceability in compliance with the most stringent regulations.

5. SURGERY

Surgery is performed under local anaesthesia or conscious sedation. B&B Dental can provide a temporary restoration in PMMA [acrylic] to be positioned while waiting for tissues to heal completely.