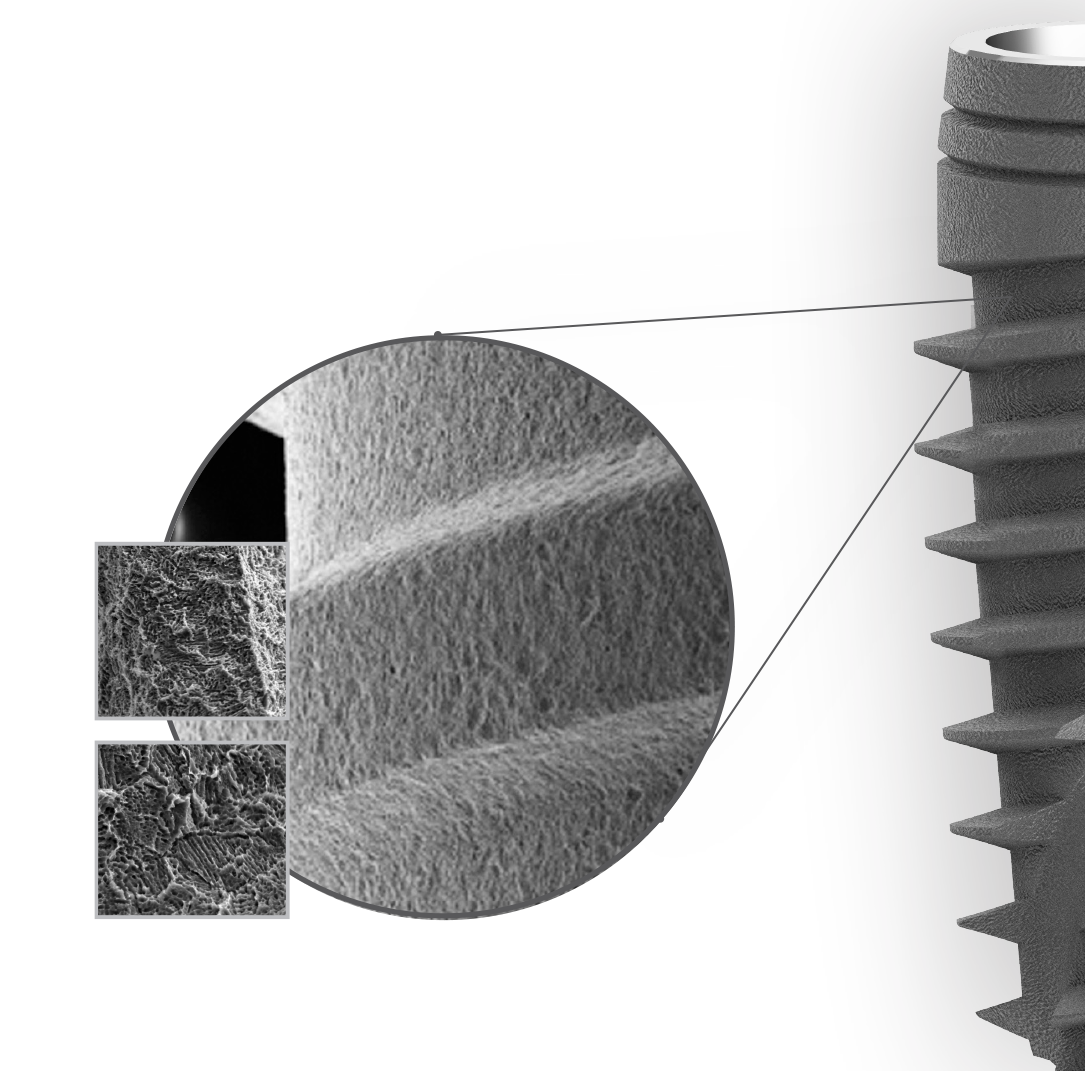

SURFACE TREATMENT

DOUBLE ETCHING TREATMENT

Two very delicate phases - which B&B Dental entrusts to sector experts - that are subject to periodic inspections. This enables us to obtain a uniform surface and a ready-to-use sterile product.

The chemical etching process creates a micro-roughness on the surface, at a microscopical level, allowing an optimal osseointegration.

SUPPORT & DEVELOPMENT

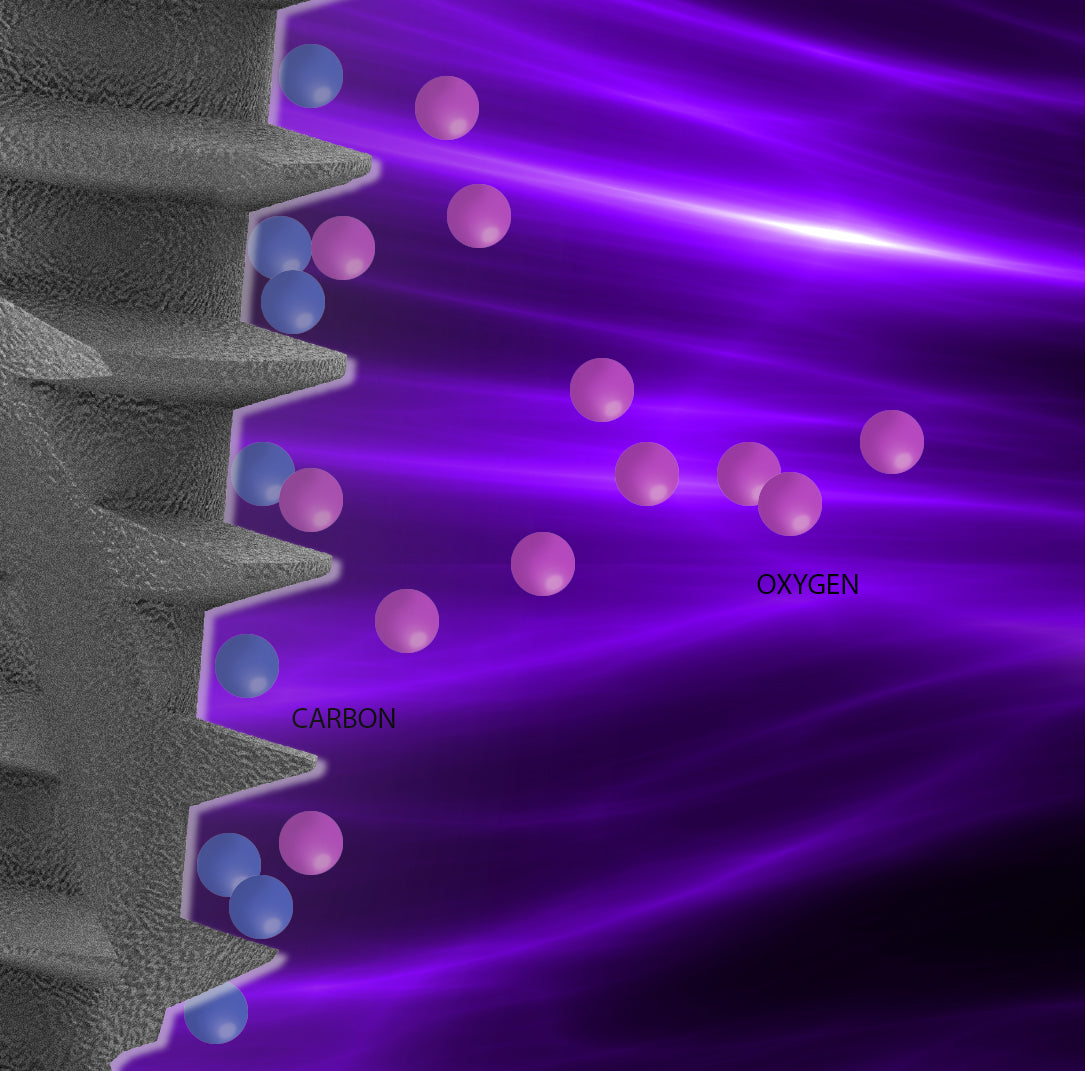

PLASMA STERILISATION

B&B adds one more stage to the implant surface for the cleanest implants. The last step before packaging is the sterilization with gamma rays. By functionalising the surfaces with atmospheric pressure plasma, the surface is cleaned, the implant is sterilised, and the risk of infection is reduced. Plasma treatment increases the surface energy and thus improves the wettability of the implant.

SUPPORT & DEVELOPMENT

final product of the highest quality

CNC MACHINE PRODUCTION

Computer numerical control machines managed by our engineeers, qualified mechsnics and qualified technicians to ensure the highest degree of connection accuracy.

CLEANROOM PACKAGING PRODUCTION

B&B is one of the very few companies that produces its own implant packaging with in-house clean room, guaranteeing cleanliness and sterility.